TO LEARN

FOR USE

A manual and knowledge page so that you can enjoy your Wheel-Tec wheels to the maximum.

TIRE PRESSURE

Points of attention

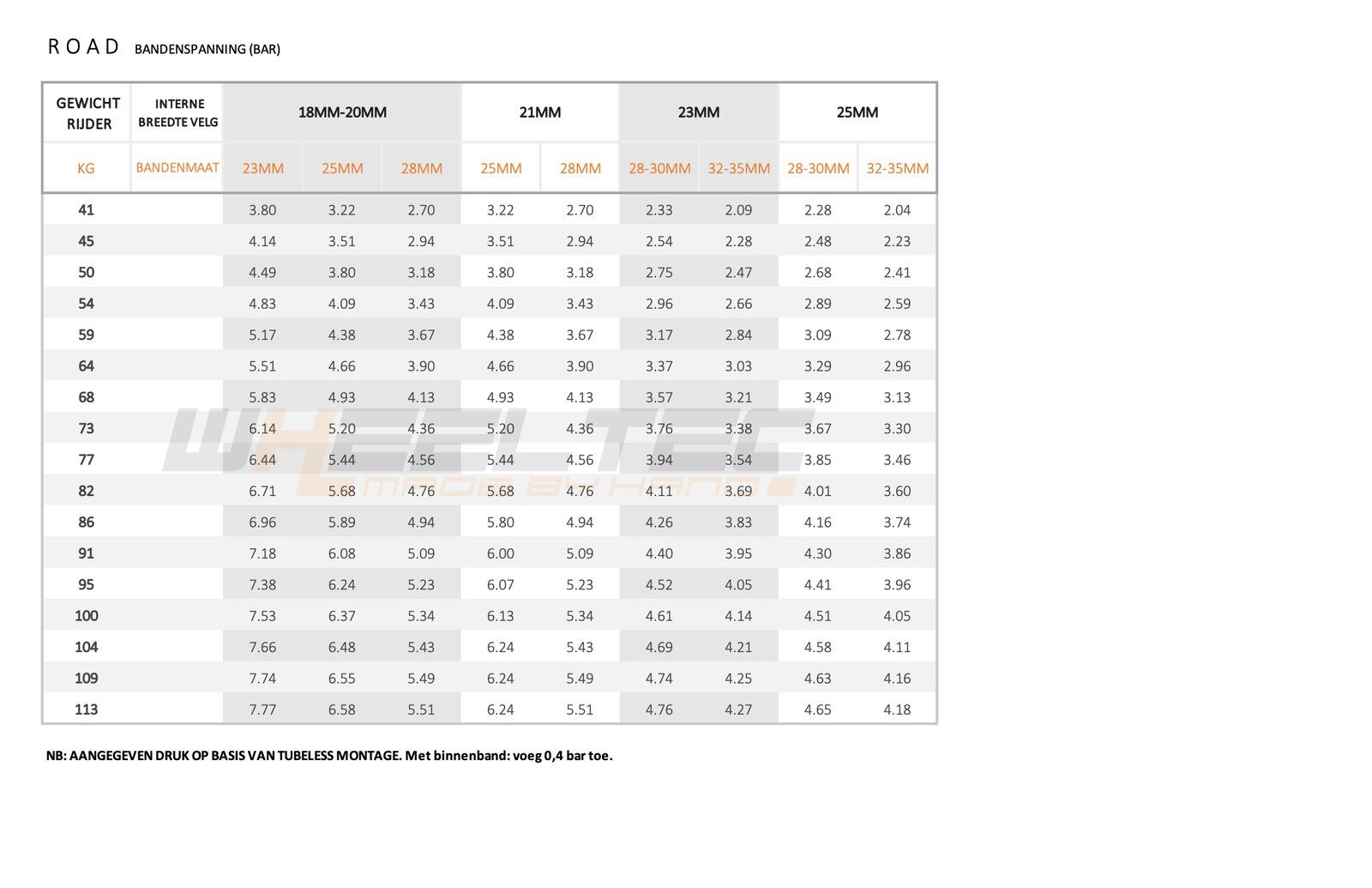

ROAD

With a road tire we increasingly want to prevent a (too) high tire pressure, which leads to loss of grip, comfort and control. In addition, contrary to popular belief, this increases rolling resistance. (click on image to enlarge)

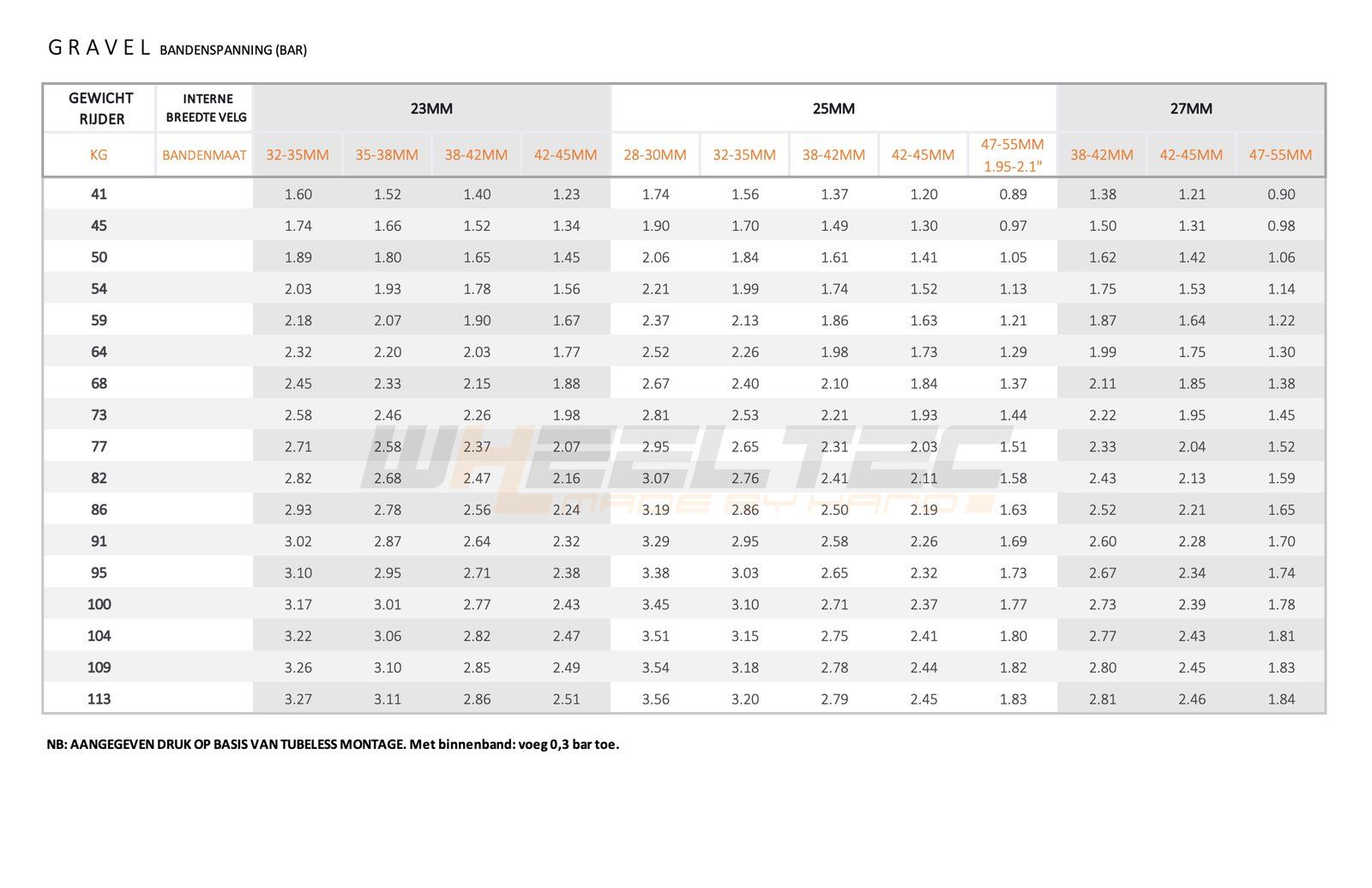

GRAVEL

With a gravel tire it is important to keep the tire pressure as low as possible for an optimal driving experience. High tire pressure leads to loss of grip, comfort and control. And it increases - contrary to popular belief - rolling resistance. (click on image to enlarge)

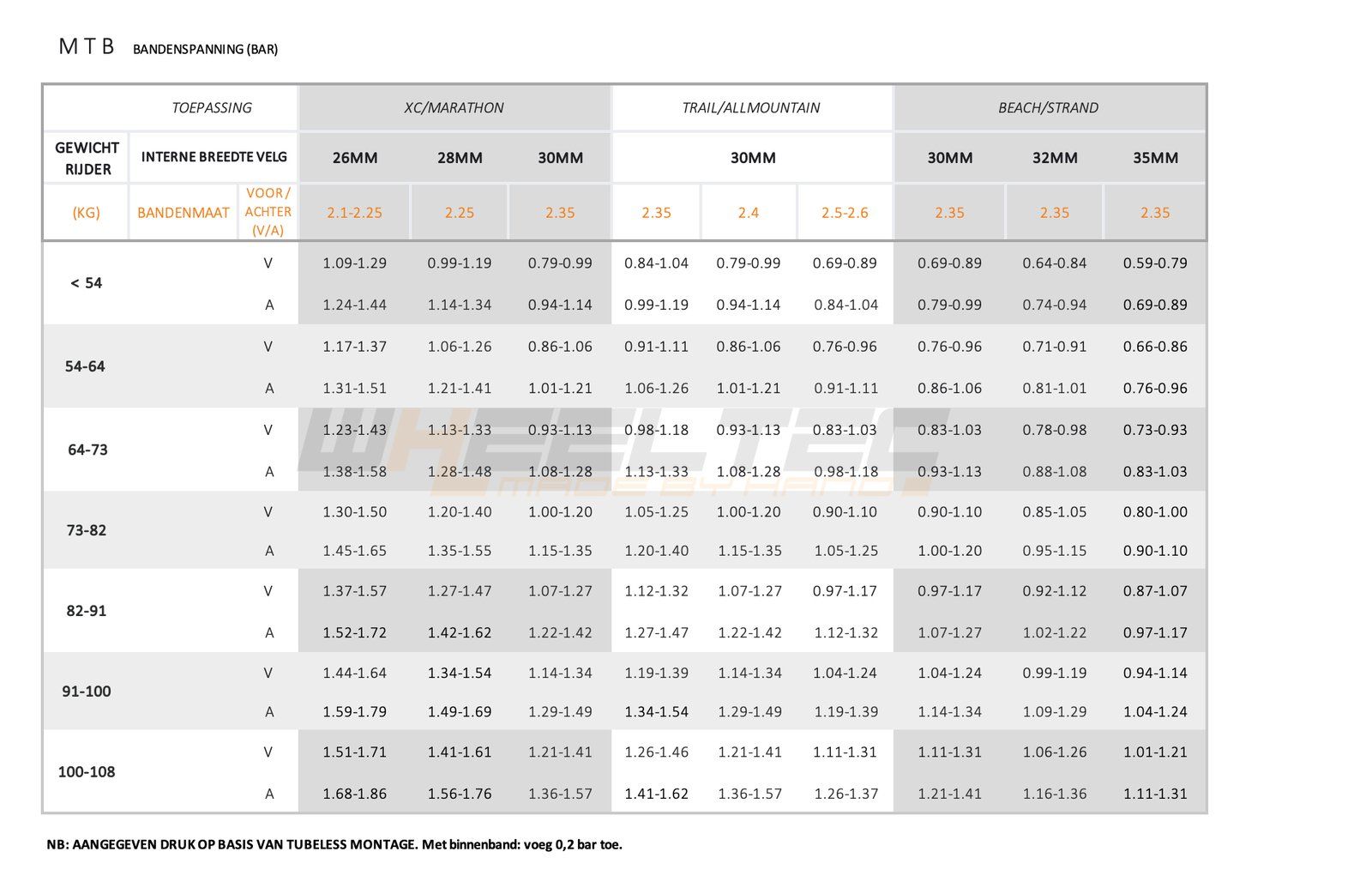

MTB

With an MTB tire it is important to keep the tire pressure as low as possible for an optimal riding experience. High tire pressure leads to loss of grip, comfort and control. And it increases - contrary to popular belief - rolling resistance. (click on image to enlarge)